Builders Report: cost, advantages, and what to expect

Everything You Need To Know About Your Builders Report

When you are buying a house there is nothing more important than making sure that the property is safe, and that you’re actually receiving what you’re being sold on. One of the best ways to make sure the property that you’re buying is a safe place for you to live (and is worth the money the seller is asking!) is to get a builders report.

Sellers also utilize builders inspection report as a way to assure prospective buyers, shorten the close time on their property, and as a part of the valuation process.

There is significant value in getting an inspection completed by someone who can do a builders report, NZ homebuyers are under increasing pressure to buy homes without contingencies to speed the process along. While a quick close might be desirable, we don’t think it’s more important than protecting yourself and your investment.

So, with that in mind, let’s take a look at the basics of builders reports in New Zealand.

What Is A Builders Report (NZ)?

A builder’s report is a detailed inspection of the structural aspects of the property you intend to buy. It will assess a range of areas and factors that play into the overall stability and adherence of the property under the NZS 4306:2005 Residential Property Inspection.

What’s Included In A Builders Report?

A lot! All jokes aside though, a detailed building report might seem like overkill but spotting that patch of damp in the far back corner might just save you from extensive structural work a few years down the line.

You can download an example builders report here to see the kind of things we look for during an inspection.

Why Should You Get A Builders Report?

Many people think of the costs and the time it can take to complete as disadvantages of a builders report, but is saving a relatively small amount of money worth going into one of the largest financial decisions you’ll ever make without knowing the state of the asset you’re purchasing?

We believe that knowledge is power and even if you receive an unsatisfactory builders report you can use that knowledge to your advantage. If you know the exact state of the property you can withdraw from a potentially damaging financial situation, renegotiate terms, or go ahead with the sale knowing exactly what you’re getting into.

How Much Does A Builders Report Cost?

The price of a builders report can very widely depending on your unique circumstances, and any quote should ask you:

– How big is the property? The number of bedrooms is important, but not as important as the overall size of the building. For example, a two bedroom house with ensuites, two guest bathrooms, a recreation room, TV room, a formal dining room, two offices, and a gym is likely to be far more work than a two bedroom house with one bathroom, living room, kitchen, and dining.

– What type of property is it? Apartments, freestanding houses, terraced houses, townhouses – they all have their unique aspects.

– How complex is your property? Multiple stories and alterations to original plans can impact your inspection.

– How old is the house? The age of the property and the materials used also need to be taken into account.

Getting a quote

Talk to us today about creating a free, no obligation quote – or just fill out the form below and we will get back to you as soon as possible.

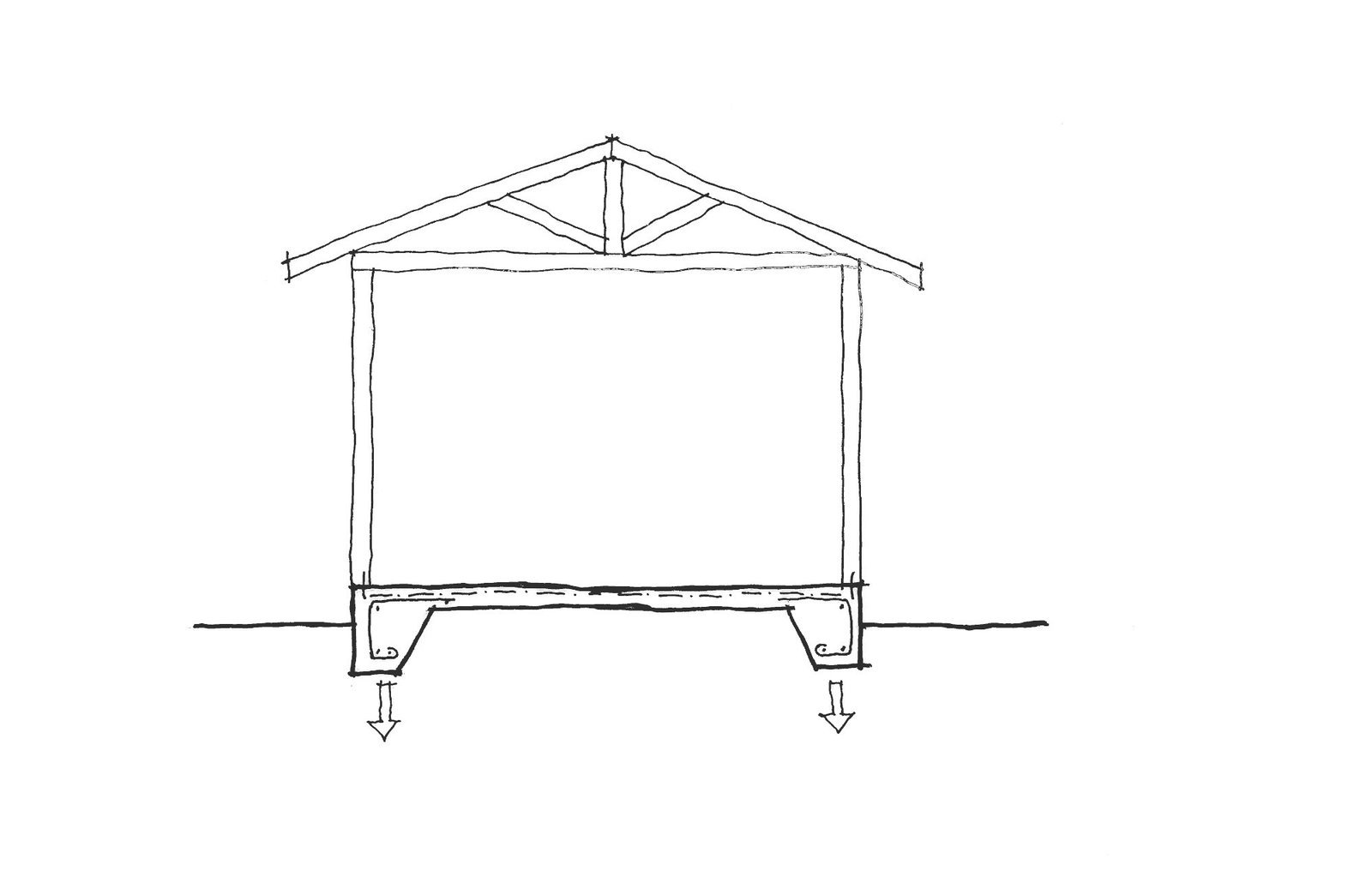

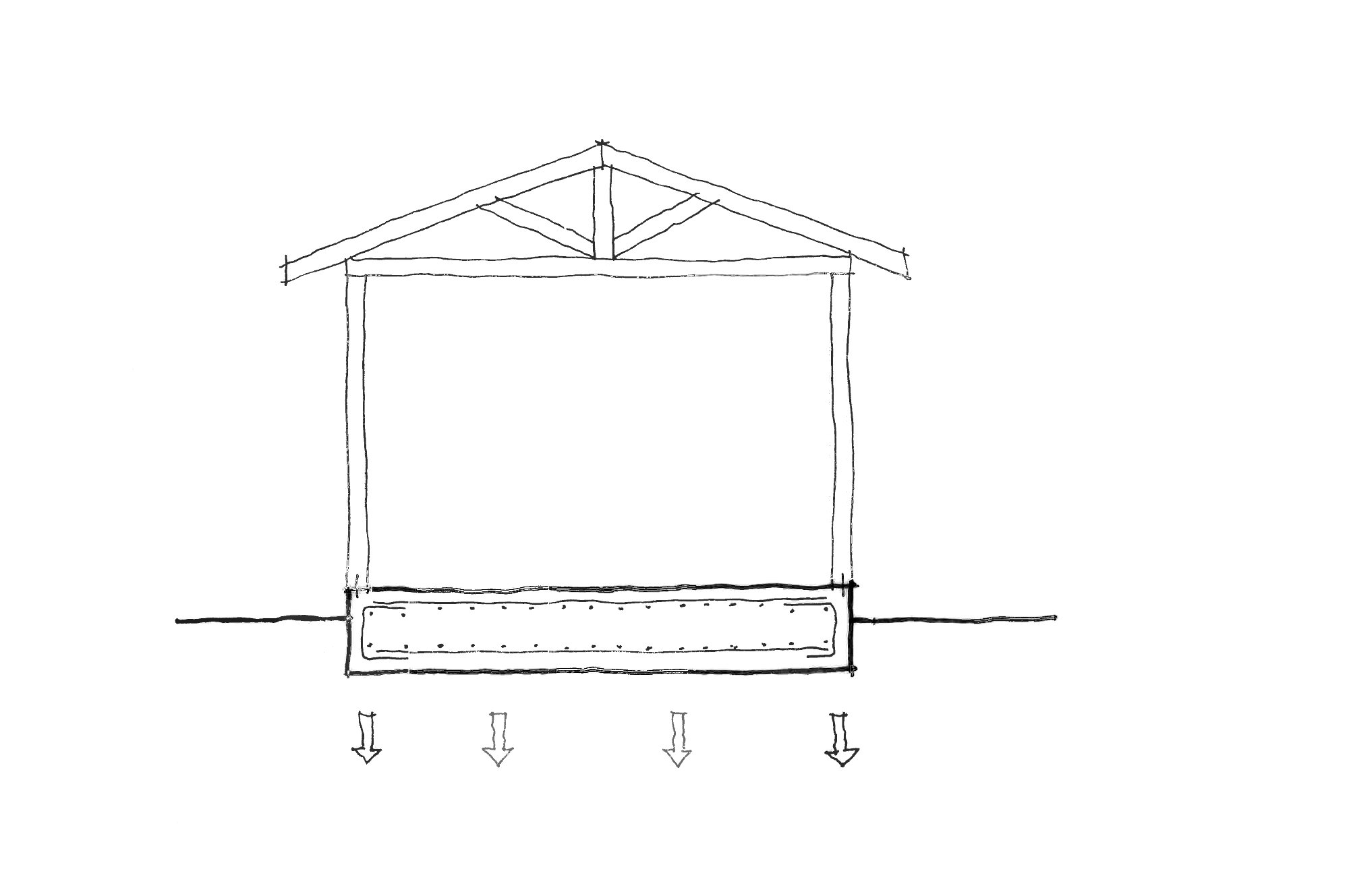

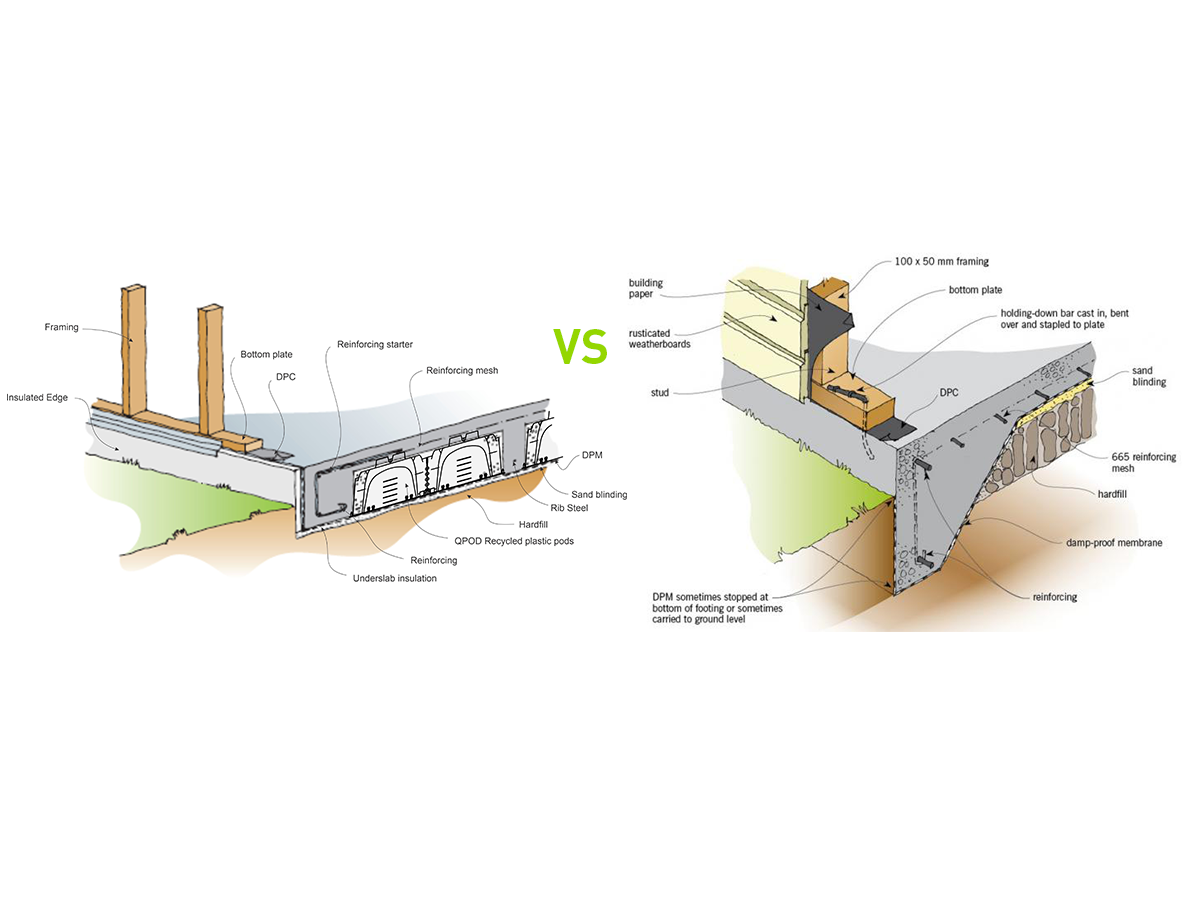

Raft foundation vs conventional foundation

Raft foundation vs conventional foundation